- Home

- Technologies

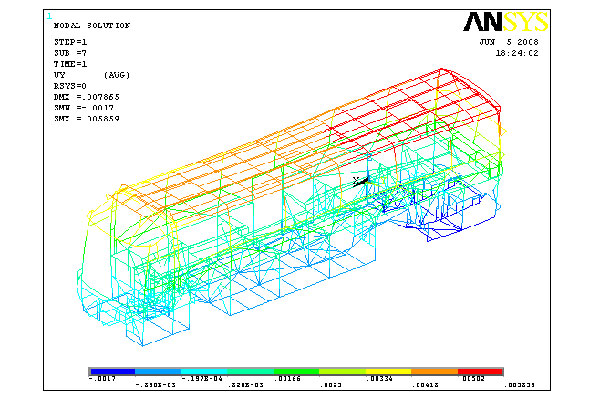

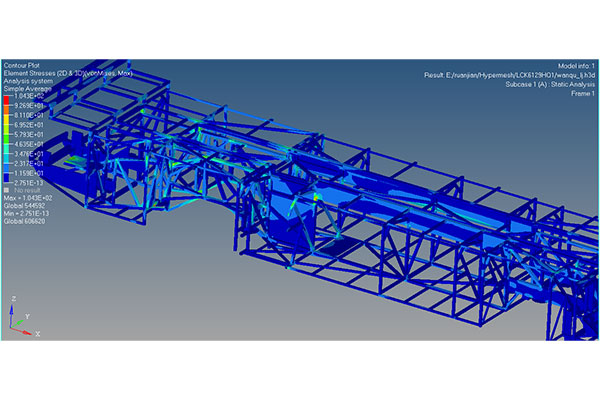

Reliable Bus Frame

The bus' frame is designed with lightweight and closed ring structure. Finite element analysis technique is employed to enhance the weak points of the frame accordingly and to improve the structure's durability.

We strive to provide the interior quietness and ride comfort for our customers. The advanced new NVH techniques such as Acoustic Black Holes (ABH) and Acoustic Metamaterials were intensively studied and aggressively commercialized to the bus/coach NVH (Noise, Vibration and Harshness) applications. Those patented technologies make the Zhongtong Buses standing out in the very competitive bus markets. We spent a lot of efforts to benchmark, design and develop, test, verify and validate our products to make sure our design ideas realized in our products in markets.

Imported 3D NC Plasma/ Laser Cutting Technique

We use 3D NC plasma cutting machine whose working precision reaching 0.03mm/M to cut the skin that will be covered on bus. Principal accessories of the bus are processed with imported 3D NC laser cutting machine, the cutting accuracy of which is 0.01mm/M. Spare parts of our buses are guaranteed of high precision. The combination of advanced processing equipment, humanized design, and strict inspection system makes Zhongtong bus a superior one among Chinese bus suppliers.

Imported Robot Welding Technique

In the bus industry, Zhongtong is a leading manufacturer to introduce robot welding technique into bus production line. Compared with manual manner, robot welding is unparalleled in terms of welding quality, accuracy, and efficiency. All of the components of closed ring structure (top beam, double column of passenger door) are finished by robot welding technique.

Advanced Tire Mold

1. The adoption of advanced tire mold manufacturing technique from Europe and a unique horizontal tire mold structure ensures 20% of precision improvement. Zhongtong is one of the first manufacturers in China possessing the capacity of making molds for all of the frame parts in bus production line.

2. The tires and the frames are assembled automatically, ensuring the tires' precision and quality stability.

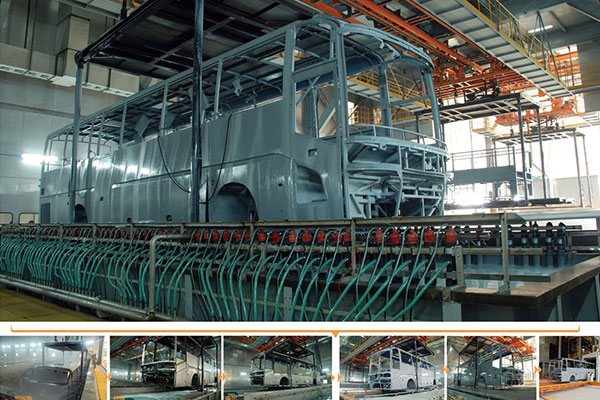

Internationally Advanced Cathodic electrophoresis Technique

Electrophoresis: Zhongtong bus owns the most advanced and most automated complete vehicle electrophoresis production line in the industry, including more than 20 procedures, which highly improves product durability, endures coating quality, and improves products life cycle.

Automatic Spraying Robot from ABB (Switzerland)

The automatic spraying robot system is distinguished for accurate spraying, little paint consumption, short work cycle, wide working region, large load bearing capacity, and reliable performance. The unique Integrated Process System (IPS) developed by ABB offers high-speed control for paint supply and closed loop adjustment, ensuring the uniformity of painting.

Automatic Hot Melt Coating Technique

With the coating speed and the glue consumption controlled automatically, the coating operation is conducted uniformly and stably, effectively avoiding the phenomenon of bubbling or shedding. Besides, it will do no harm to operators' safety.

Automatic Cutting Technique for Floor Mat

The material cutting process is supported by the cutting equipment from EASTMAN (America), and performed according to the CAD drawing. It features high material utilization rate (96%) and high efficiency (improved by 60%), dramatically improving the quality of floor mat and reducing workers' labor intensity.

Wheel Alignment Equipment from America

We have employed the advanced wheel alignment equipment to test the bus's 4 wheels and control some vital parameters like front axle, Kingpin caster, camber angle, Kingpin inclination, and propulsion line. This system contributes to reduce wear abrasion, ensure welding quality, and add to driver's comfort.

Zhongtong Bus Holding Co., Ltd.

Add: No. 261 Huanghe Road, Liaocheng Shandong Province, China

Fax: +86-635-8322340

E-mail: overseamarketing@zhongtong.com